What are the top construction trends in 2026 and which skills will matter most?

The UK construction industry is reaching a critical turning point. With tighter regulations, smarter technology, and fewer skilled workers, the landscape is changing rapidly. Anyone working in the sector needs to prepare now. This guide explores five major trends and the practical, futureproof skills that will help you keep pace.

The CITB Construction Skills Network forecast shows significant labour demand across digital, sustainable, and modern methods with clear implications for site readiness and workforce development.

Here's What We Have Covered In This Article

1. Modular Building Methods Are Booming

Modular construction and offsite assembly are being adopted more widely across the UK. These modern building methods reduce waste, lower site disruption, and speed up project delivery.

What is Design for Manufacture and Assembly?

Design for Manufacture and Assembly, or DfMA, involves creating building components in a factory and assembling them on site. It relies on precise planning, smooth construction logistics, and collaboration across trades.

Why modular methods matter:

- Faster delivery and installation

- Reduced disruption and downtime

- Consistent material quality

Skills worth developing:

- Interpreting preassembly designs

- Coordinating sequencing between teams

- Understanding fabrication schedules

Who is impacted:

- Joiners and installers

- Site logistics coordinators

- Offsite construction supervisors

Modular Methods: Quick Q&A

Q: Isn’t modular just flat pack buildings?

A: No. Today’s modular systems include high rise housing, hospitals, and commercial buildings. They’re precision engineered and built to strict quality standards.

Q: Does modular work reduce trade demand?

A: Not at all. It shifts the work off site, meaning skills like electrical installation, plumbing, and joinery are still essential just in a different setting.

Major contractors such as Laing O’Rourke and Mace Group are already leading with Modern Methods of Construction. Building familiarity with these systems gives workers a valuable edge.

Modular methods demand coordination, planning, and offsite awareness skills that are becoming essential on UK job sites.

Pro Tip 1: Learning how to read BIM models now will give you a strong edge on digitally led sites.

2. Building Information Modelling and Digital Twins Are Reshaping Site Operations

Data driven construction is becoming the new norm. Building Information Modelling (BIM) and digital twins allow teams to visualise, test, and coordinate projects in a virtual space before a single brick is laid.

What should workers understand?

-

BIM Levels 2 and 3 create shareable models for every trade

-

Common Data Environments (CDEs) hold up to date documentation

-

Digital twins mirror live site conditions for better oversight

Skills for future site roles:

-

Navigating federated BIM models

-

Running clash detection scans

-

Using digital workflows to share updates

Many teams now rely on platforms like Autodesk Revit and Trimble. Knowing how to navigate these tools supports stronger collaboration, reduces errors, and keeps information consistent.

Working within the BS EN ISO 19650 framework ensures your digital processes align with best practice. Developing your site digital literacy and data coordination skills will set you apart.

BIM and digital twins are reshaping planning and communication and workers who can use them will be indispensable.

An AI photo of NVQ Construction Training in Essex – MOS Training Centre

Pro Tip 2: Even basic carbon literacy training can help you stand out on sustainable builds.

3. Artificial Intelligence and Automation Are Transforming Job Sites

Smart tools are now an everyday part of UK construction. Drones, automation systems, and predictive software are helping teams build faster, safer, and more accurately.

What tools are being used?

-

Drones for visual mapping and defect detection

-

Automated layout machines for precision

-

Predictive tools for forecasting delays and errors

In demand skills:

-

Analysing AI site data reports

-

Monitoring automated equipment

-

Supporting predictive project workflows

New digital job types:

-

Automation technician

-

Digital site foreman

-

Construction insights analyst

New Roles Watchlist

-

Data driven logistics lead

-

AI systems coordinator

-

Drone operations supervisor

These technologies shift roles rather than remove them. Workers who understand how to use data and smart tools will play a key role on future projects.

AI in construction opens new job paths and improves accuracy the future will reward digital ready tradespeople.

An AI photo of construction course in London UK – MOS Training Centre

4. Sustainable Construction Is Now Core Practice

Sustainability is no longer a future concept it’s a present requirement. Clients, governments, and site managers are demanding low carbon, resource efficient building practices.

What’s driving the shift?

- Net zero building commitments

- Compliance with BREEAM, PAS 2080, and the RIBA 2030 Challenge

- Focus on material reuse and low carbon systems

- Guidance from the UK Government Construction Playbook

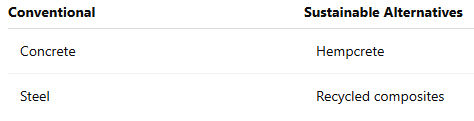

Smart material choices:

Vital sustainability skills:

- Calculating whole life carbon

- Using material passports and tracking tools

- Designing for disassembly and reuse

- Conducting carbon footprint assessments

Workers with strong sustainability knowledge are better equipped for long term careers and aligned with the UK’s net zero goals.

Low carbon construction is no longer a niche it’s a professional advantage across all trades.

5. Health, Safety and Wearable Technology Are Transforming Work Culture

Wearable safety tools and smart PPE are changing how health and safety is managed. These innovations are creating proactive, data supported safety cultures.

What’s changing?

- Real time motion and fatigue tracking with wearables

- Assistive lifting support using exosuits

- Telemetry data to spot emerging risks

Practical skills to build:

- Setting up wearable gear accurately

- Interpreting real time alerts and dashboards

- Responding quickly to prevent injury

Support for the workforce:

Not every worker will be confident using new tools. Training, clear explanations, and team-based learning can ease the transition and build trust.

Wearable safety tools empower teams and reduce injuries and workers who adopt them stay protected and in control.

How Do These Construction Trends Work Together?

Each trend is valuable on its own but the biggest impact comes when they combine:

- Modular and BIM streamline offsite delivery with digital planning

- Artificial intelligence and safety tools spot risks before they escalate

- Sustainability and data insights improve environmental performance

When tech, training, and teamwork align, construction becomes faster, safer, and more future ready.

From Today to 2026: Your Future Skills Roadmap

Start with quick wins:

- Watch a BIM model walkthrough video

- Visit a modular factory or CPD event

- Ask your site manager about current digital tools

Build over the next 12 months:

- Take CPD in sustainable site methods

- Join pilot projects using smart PPE

- Work alongside automation specialists when possible

Set long term development goals:

- Gain higher NVQ qualifications

- Take on mentoring in digital site practices

- Explore the T Level in Design, Surveying and Planning with MOS Training Centre support

The MOS Training Centre offers skills bootcamps and fast track training aligned to these roles. Taking part prepares you for the modern construction workforce.

What Can You Do Right Now?

- Choose one new trend or skill to explore this month

- Join a short training course or skills bootcamp

- Talk to your team about what the next 12 months look like

By acting now, you put yourself in control. The industry is changing but with the right steps, you can change with it and stay ahead.

Upgrade Your On Site Skills

Fast track your NVQ with real site assessments and tailored training from MOS.